Ernie Ball Electric Guitar Strings

Smelting

Smelting

Alloys used for strings begin from ore which is smelted utilizing high temperature to remove impurities. The material is cooled and forged into form for transformation to cable. Our unique alloys employed for Cobalt Slinky, M-Steel Slinky, and Aluminum Bronze strings tend to be smelted to the exacting specs to make sure optimum performance and persistence.

Raw MaterialsOur strings are manufactured because of the best and freshest recycleables that are specified to exacting tolerances assure optimal consistency and performance. Strings include fine diameter wire which is furnished on spools. Each type of sequence is made from a certain combination of line materials and sizes.

Ball End Fabrication Guitar and bass basketball stops are formulated utilizing metal line rod. The brass is machined and cut to exacting requirements to make sure an accurate fit and purpose. The baseball stops tend to be after that deburred, washed, and inspected before these are generally ready for use.

Guitar and bass basketball stops are formulated utilizing metal line rod. The brass is machined and cut to exacting requirements to make sure an accurate fit and purpose. The baseball stops tend to be after that deburred, washed, and inspected before these are generally ready for use.

Wound strings contain a core and a wrap layer. Cores are manufactured by cutting hexagonal shaped wire to size and twisting one end with a specific shape and twist matter to add a ball end. Once made, cores are filled onto winding machines which spin the core while laying a consistent winding of place line round the core.

Wound strings contain a core and a wrap layer. Cores are manufactured by cutting hexagonal shaped wire to size and twisting one end with a specific shape and twist matter to add a ball end. Once made, cores are filled onto winding machines which spin the core while laying a consistent winding of place line round the core.

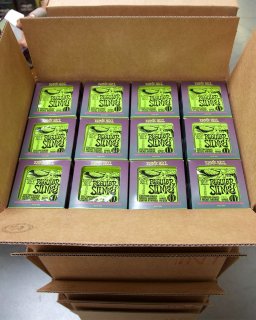

Ernie Ball single strings tend to be coiled and packaged individually if you wish according to particular Slinky measure needs. The Slinky sets are then processed and flow covered with atmosphere tight individual foil packs.

Immersion TestPackaged strings are checked for a quality seal utilizing a pressurized water chamber which subjects packs to an increased standard of tension across every seal. This ensures that the bundles are entirely environment tight and top-notch the seal is optimal.

Boxed And Ready To Ship